Product display & introduction

Current position:Home > Songzheng Products Display & Introduction

<

>

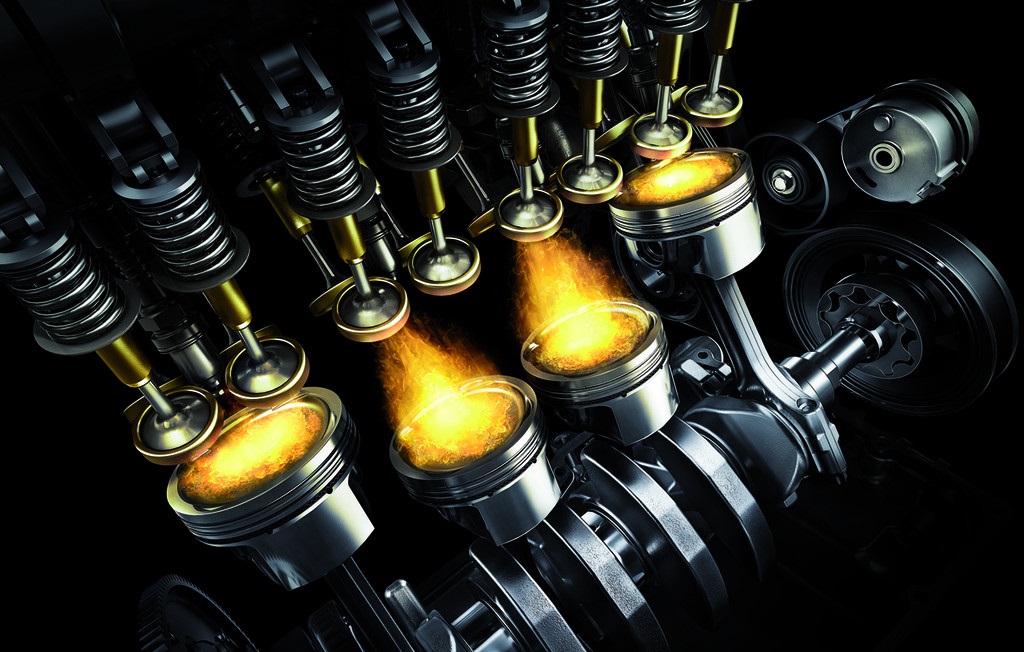

About the valve

The role of the valve

The composition of the valve

The shape of the valve

Materials

Motorcycle valve

General purpose engine valve

Diesel valve